Engine Modernization

Modernization for Optimization

Peaker Services, Inc. modernizes large industrial engines to optimize efficiency and performance, increase reliability and safety, reduce operating/maintenance costs and exhaust emissions, and simplify operation and maintenance. We’ve retrofitted over one thousand diesel, diesel-pilot dual fuel, bio-gas, landfill gas, synthetic gas, and natural gas engines with mechanical and digital technologies, bringing unique solutions to unique problems. An engine must be appreciated as a system of processes: pre-combustion, combustion, post-combustion, and the process the engine is driving, whether a generator, propulsion system or compressor. We understand the boundary conditions and associated engineering tradeoffs as well as power plant, locomotive, ship, or pipeline applications.

PSI prides itself on listening closely to customer needs, paying particular attention to what they are trying to achieve from the board room to the engine room. All aspects from financial, technical, and user requirements are incorporated into our designs. We work side by side with our select vendors, engine dealer, service companies, and end users to learn how to most closely meet their needs.

Our experienced, multi-disciplined engineers and technicians are mechanical, electrical, and controls specialists.

Using Our Best Tools and Software

- Engine Modeling Software

- Electrical and Mechanical Design Software

- Human Machine Interface and Service Software

- 4 Large Engine Test Cells

- Instrumentation and Monitoring Software

- Crank-Referenced Cylinder Pressure | Vibration | Ultrasonic Analyzers

- Coriolis Fuel Measurement

- Portable and Rack Exhaust Emissions Analyzers

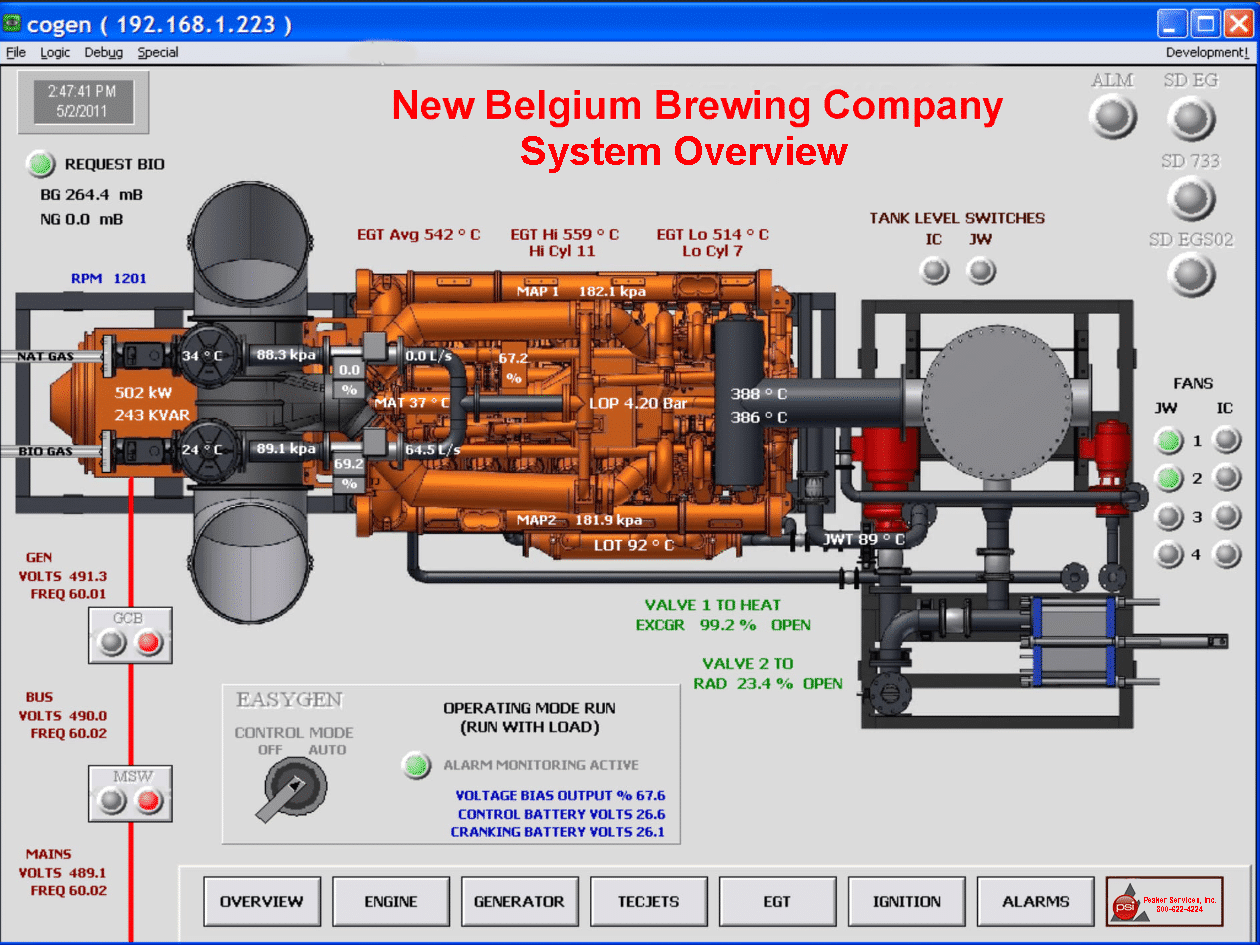

PSI uses remote monitoring of our systems to evaluate performance, predict use-based maintenance requirements, and impending component failure. The operating data helps validate our development work.

Certainly, the digitization and modernization of an engine can solve many problems and provide many benefits, however when coupled with robust mechanical modifications and seamless interfacing, an optimum solution is achieved. PSI uses industrial engine design specific and proven components designed and manufactured by Woodward, Inc. and other leading vendors. We actively participate with vendor design engineers when new products are introduced and thoroughly understand each components capability. We also manufacture our own components and interfaces for seamless integration.

Our team of sales managers, application engineers, and field technicians are ready to meet with you.

Unique Engine Solutions Include:

- Diesel Engine Redesign

- Aftercooler, Compression Ratio, Mechanical to Electronic Fuel Injection, Turbocharger Inlet Vane, etc.

- Integrated Gas Engine Control and Monitoring Systems

- Lean Burn Full Authority Air-Fuel Ratio Control/Ignition/Speed Control/Detonation/Engine Protection and Sequencing/Local and Remote Monitoring

- Lean Burn Fuel Trim Air-Fuel Ratio Control/Ignition/Speed Control/Detonation/Engine Protection and Sequencing/Local and Remote Monitoring

- Lean Burn Turbocharger Wastegate/Air Trim Air-Fuel Ratio Control/Ignition/Speed Control/Detonation/Engine Protection and Sequencing/Local and Remote Monitoring

- Rich Burn Fuel Trim Air-Fuel Ratio Control/Ignition/Speed Control/Detonation/Engine Protection and Sequencing/Local and Remote Monitoring

- Digester/Natural Gas Real Time Infinite Fuel Blending

- Single and Multi-Point Diesel Natural Gas Dual Fuel Conversions

- Multipoint Diesel to Natural Gas Conversions

- Diesel Oxidation Catalyst Systems for EPA RICE NESHAP

- Digital Control and Electric Rack/Throttle Actuation

- Remote Engine Monitoring Systems

Peaker Services, Inc.

8080 Kensington Ct.

Brighton, MI 48116-8591

T: 800.622.4224

P: 248.437.4174

F: 248.437.8280