EMD

PSI is equipped to meet the needs of our customers:

- 75-foot elevated work platform for locomotive inspection and maintenance

- 30-ton overhead crane capacity

- 200-ton electric locomotive jack capacity

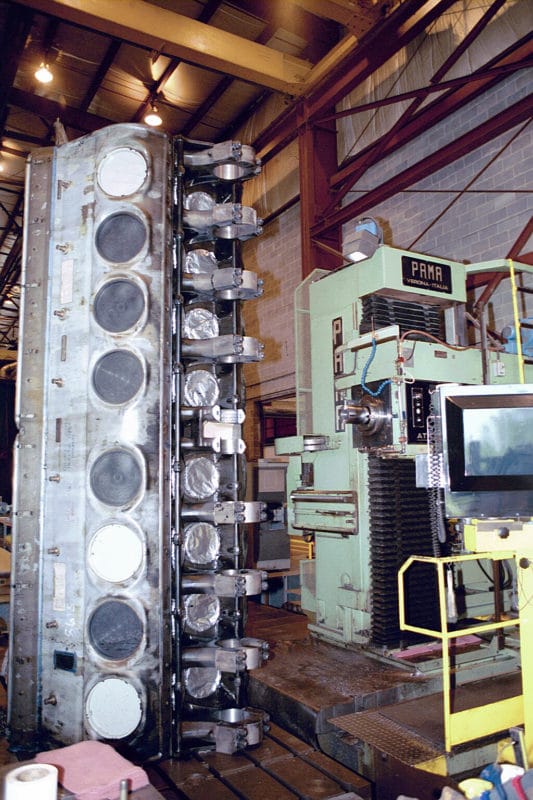

- High pressure, vertical block washer with 7-ton capacity

- Portable horizontal line boring machines

- 4-axis CNC boring mill

- Arc and inert gas welding

- Plasma cutting

- Comprehensive rebuilding equipment

- Soda blasting and paint bay

- Specially designed outdoor test cell for extended load testing of rebuilt and repaired diesel engines

- Two static large engine test cells

- EMD 645 and 710 development engines

- Coriolis fuel consumption meters

- Lab grade exhaust emissions measurement

- Combustion analyzers

- Engine modeling software

LOCOMOTIVE REPAIR AND OVERHAUL

Peaker Services, Inc. has comprehensive locomotive repair and overhaul capability. Our highly skilled craftspeople will provide you the highest quality work that perfectly matches your needs. Be they minor or major requirements, we can process your equipment through our clean and organized facility.

We offer a wide range of services for locomotives, including:

- Certified PTC installation

- Engine overhaul in place or out of the body complete remanufacture

- Generator replacement

- Truck work

- Compressor replacement

- Body repair

- Electrical trouble shooting

- Replacement of miscellaneous parts

- Inspections

ENGINE OVERHAULS AND REPAIRS

We remanufacture 567, 645, and 710 engines and test them in our onsite test cell. We will build to your specification, help you develop one, or supply one that will meet your needs.

Our process:

- Teardown the engine completely

- Clean the crankcase, pan, and components to bare metal

- Identify all important parts with our tagging system, which ensures your parts are accounted for

- Undertake a thorough inspection by experienced, trained PSI technical staff

- Conduct non-destructive (NDT) magnetic particle testing of critical parts

- Check and measure all critical areas on engine

- Make repairs as required to OEM standards

- Check all threaded holes and repair

- Rebuild all components (process addressed in component section)

- Rebuild case and pan (process addressed in case and pan section)

- Using state of the art cleaning equipment, CNC mill, certified tools, and welders, we repair the various parts to OEM standards

- The engine is assembled, again to OEM standards using all new gaskets and bearings

- After complete assembly, your engine is load tested to your requirements

- After load test engine is inspected, re-torqued and painted

- All build sheets and load test data are collected then supplied to you for your records

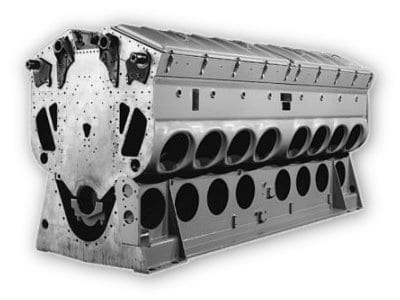

CASE AND PAN

When you want the highest quality, look to PSI for rebuilding or repair.

To ensure that your assembly meets OEM specifications, we:

- Clean the crankcase, pan and components to bare metal

- Undertake a thorough inspection by experienced, trained PSI technical staff

- Conduct non-destructive (NDT) magnetic particle testing of welds and high stress areas

- Check crankcase line bore with precision gauges, and retain all measurements for future reference and quick accessibility

- Check all threaded holes

As needed, we then:

As needed, we then:

- Repair cylinder pot cracks

- Repair test cock tube cracks

- Correct crankcase line bore

- Repair A-frame cracks

- Repair any structural damage

- Repair main bearing serrations

- Restore mounting pad surfaces

- Repair hand hole window

- Repair threaded holes

- Restore cylinder pot surface

- Resurface the exhaust deck

- Remachine the end sheets

Following the comprehensive rebuild or repair, the reconditioned unit is shipped to you for equipping and installation. If you’d prefer, PSI will handle the refitting.

All PSI rebuilt case and pan assemblies meet OEM specifications and are backed by a PSI 1-year warranty.

To keep your equipment running, contact PSI for rebuilt engines.

CUSTOM ENGINE REPAIR

COMPONENT ASSEMBLY

You need reliability and performance, which is what you get with PSI quality rebuilt components and assemblies.

Power Assemblies

PSI rebuilds power assemblies, either turbocharged or naturally aspirated, for locomotives, power generation, marine applications and general industrial use. As required, PSI will also build power assemblies to meet specific customer needs.

As part of our rebuilding process, we:

As part of our rebuilding process, we:

- Undertake a thorough inspection by experienced, trained PSI technical staff

- Conduct non-destructive (NDT) magnetic particle testing of cylinder heads and connecting rods

- Check all dimensions, with precision bore gauges, and retain all measurements for future reference and quick accessibility

- Install new valve guides

- Check for valve leakage with sensitive vacuum testing

- Torque each assembly to OEM standards

Note: Power assembly models 567BC, C, D, 645E, 645F, and 710G are available for unit exchange.

EMD 567, 645, and 710 Oil Pumps and Water Pumps

All pumps are completely disassembled, inspected and measured by the experienced, trained PSI technical staff. Worn and/or damaged parts are repaired or replaced following OEM standards. Consumable items are replaced with new ones.

All pumps are completely disassembled, inspected and measured by the experienced, trained PSI technical staff. Worn and/or damaged parts are repaired or replaced following OEM standards. Consumable items are replaced with new ones.

Note: All Oil Pumps and Water Pumps are available for unit exchange.

Governor Drives & Auxiliary Drives

All governor drives and auxiliary drives are completely disassembled, inspected and measured by the experienced, trained PSI technical staff. Worn and/or damaged parts are repaired or replaced following OEM standards. Consumable items are replaced with new parts.

All governor drives and auxiliary drives are completely disassembled, inspected and measured by the experienced, trained PSI technical staff. Worn and/or damaged parts are repaired or replaced following OEM standards. Consumable items are replaced with new parts.

Note: All Governor Drives and Auxiliary Drives are available for unit exchange.

Woodward Governors and Actuators

PSI is proud to be a Woodward Governor Company authorized Service Facility. We sell and service the Woodward line of engine governors and actuators.

PSI is proud to be a Woodward Governor Company authorized Service Facility. We sell and service the Woodward line of engine governors and actuators.

Remember: All PSI rebuilt components and assemblies meet OEM specifications and are backed by a PSI 1-year warranty.

Peaker Services, Inc.

8080 Kensington Ct.

Brighton, MI 48116-8591

T: 800.622.4224

P: 248.437.4174

F: 248.437.8280

As needed, we then:

As needed, we then: